During a break from today’s decorating (well, yesterday’s, I guess, now it’s after midnight) I watched a few YouTube things. One of the suggested videos I spotted was a PBS Wyoming thing called Brotherhood of the Broadaxe (see below), which I thought sounded intriguing.

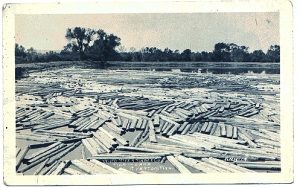

The story of the Wyoming Tie-Hacks, and the Tie-Drives, where thousands of trees are felled, and the resulting logs are turned into rough ‘ties’, for the ever-expanding railroad network, being sent from remote camps by flume and river, is fascinating.

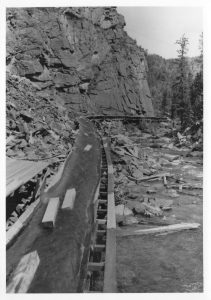

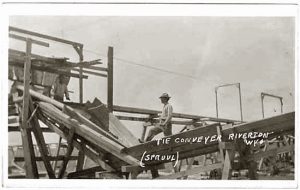

The log flumes were miles long. The Warm Spring flume looks, on maps, to be about five miles or more. Note the guy perched on the catwalk in the above pic. Precarious!

In the period and location which this documentary covers, not one fatality occurred under the auspices of the Wyoming Tie and Timber Co.

When you consider the extremely hard work, long hours, and the vast volumes of timber cut down, prepared and transported, using only hand tools and very primitive methods of transport and processing, that is really quite amazing.

The industry, a short-lived boom created by the burgeoning rail network, but soon to be rapidly superseded by industrialisation, lasted only one generation. It was a hard life. But judging by the accounts of those interviewed for this film, a good one… fascinating!

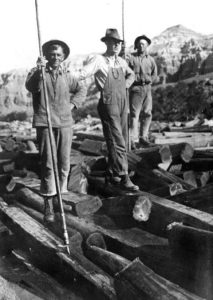

The Scandinavians were a big part of this particular epoch, with the Wyoming Tie & Timber Co. set up by a guy who’d done similar work back home in Norway. He got a lot of folks from the ‘old country’, and Sweden, to emigrate, and they formed the nucleus of the business.

Local Indians and other more or less ‘native’ Americans would fill out the teams and bulk up the numbers, especially during the Tie Drives, after the Scandiwegians and other more expert Tie Hacks had done the felling and hacking, getting the wood from source to destination.

Hearing the old-timers and their wives and children reminisce about this period, it sounds both very hard, and yet very satisfying. The work was intense and seasonal, the logging locations were remote, and incredibly beautiful. Winters were hard, and skiing was an essential daily skill.

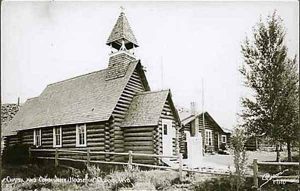

The Wyoming Tie & Timber Co. really looked after their workers, building homes and camps, buying the employees kids Christmas gifts, and feeding the workers well (tourists would sometimes stop to watch the work, and were even invited to feast on the abundant victuals!). They even had programmes to look after the older less able men.