After our car died last Thursday, the AA got us home. At a not inconsiderable cost. So… with no money for repairs, what to do? I decided to get her up somehow, for inspection. I tried using a trolley jack I have, and some ordinary jacks. But no dice.

It was time to buy some ramps. Halfords in March did’nae have any. But the Wisbech branch had some, for £45 a pair. But without wheels, how was I to get ‘em? Fortunately our pal Ken was kind enough to give me a lift to Wisbech, so I could collect them. Cheers, buddy!

The ramps will be very useful if I need to access the underside of the vehicle/engine bay. And I imagine I will need to. But I didn’t need to today. Thanks are also due to our neighbour, Sean, for helping me get the car up on the ramps.

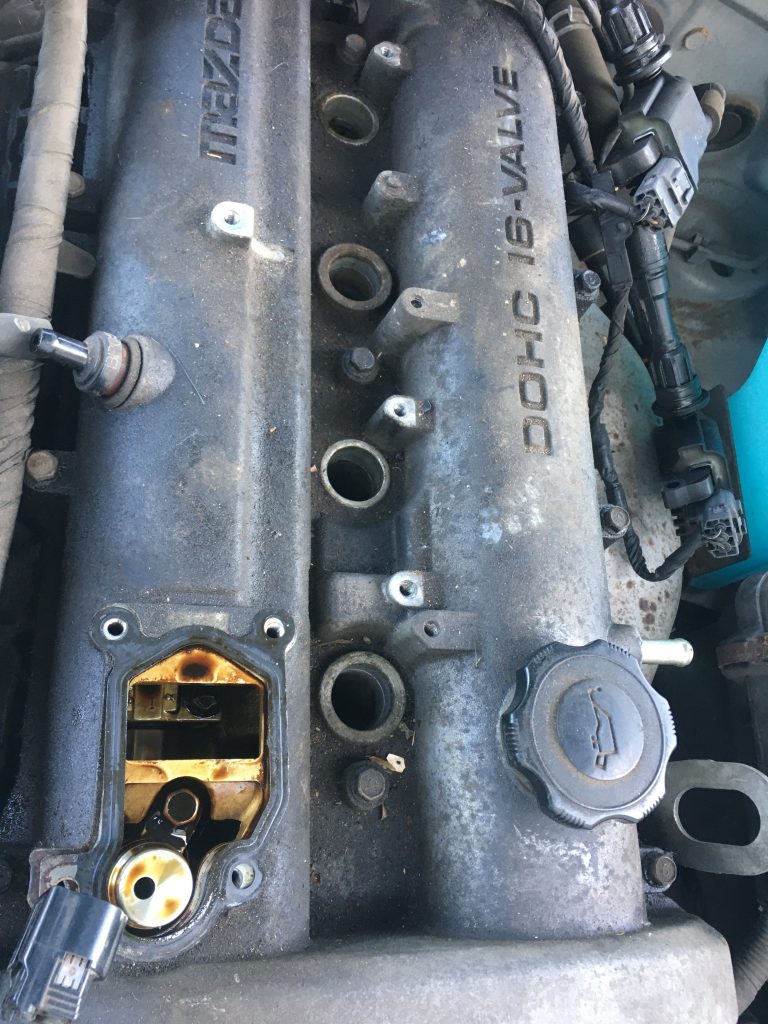

I decided to photograph each step. And, starting with the picture above, that’s what this series of photos depict. All I was doing today was removing the ‘rocker cover’. So I could see if the cam-belt was indeed, as the AA engineer believed, broken.

The first thing I discovered on starting this job is that YouTubers routinely make things look very easy. Usually they’ll be doing stuff they’ve done many times before. But if you’re not used to whatever it is? As an example, disconnecting some of the wiring junctions proved much harder than expected. It’s amazing how discouraging that can be!

Gradually things got easier. Which was encouraging. The hoses all came off very nicely and cleanly. This was a relief, as old tubing can be brittle and perish, etc.

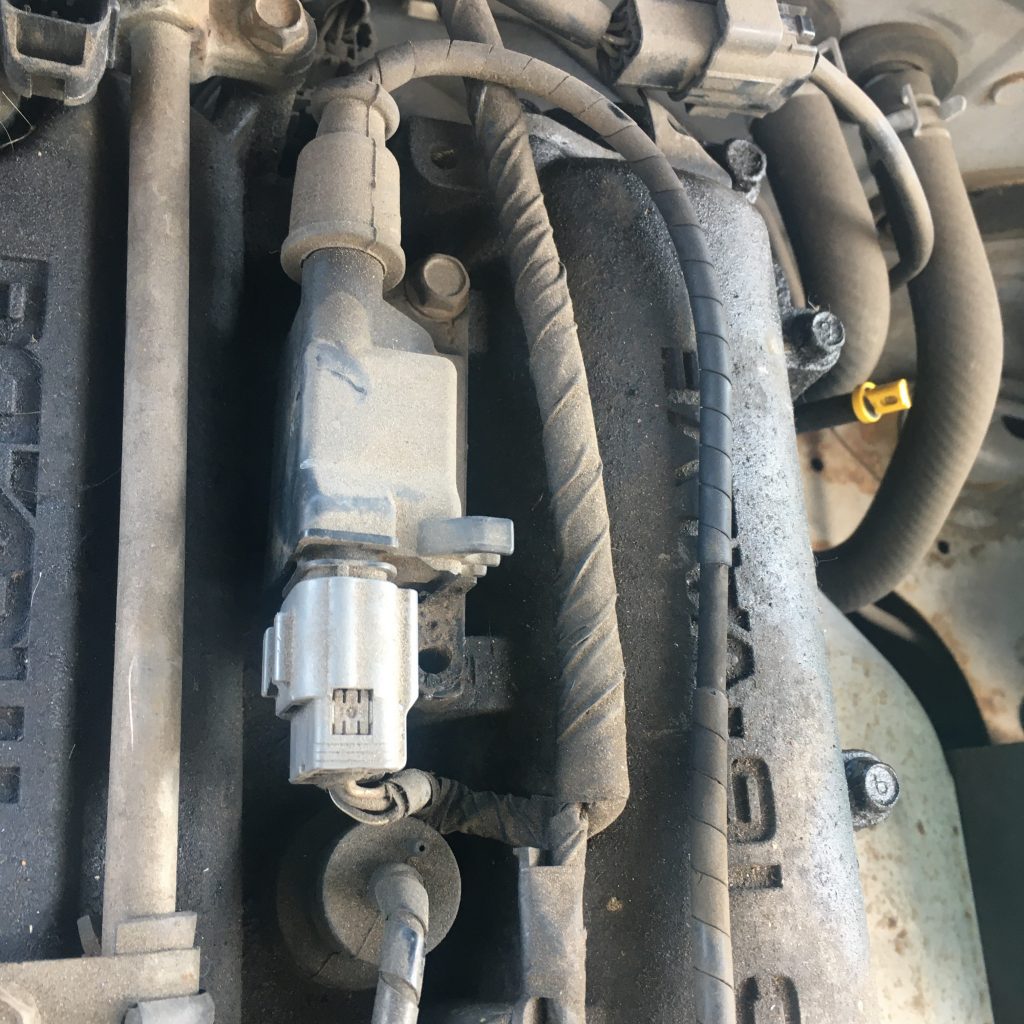

The above photo shows a point where a male peg goes into a female hole. But it wasn’t actually connected. This one was at the back. There was another, pictured below, on the left side of the engine.

One thing that really spooked me was the long doodad in the image below, below the spark plug wiring. None of the YouTube videos I watched had any such parts, so I was stumped. Nor could I find any diagrams online that explained this mysterious appendage.

Luckily I stumbled across a video by an American dude that clarified the matter. Turns out it’s a thing called a VVT, or Variable Valve Timing mechanism. Guess I might need to look into that?

One thing I didn’t photograph, and should’ve, was a 19mm nut at the rear of the engine cover, that was a real mother to loosen. I had to use a mallet to get that loosened off! Once I’d done that I was able to lift the whole thing up and secure it with a bungee cord.

As the photo below shows, I tried to arrange my nuts n bolts in such way that they’d be easy to replace in their proper order.

As can be seen below, I got the spark plugs out okay, these were, once again, rather different to anything I’d seenYouTubers dealing with. Fortunately if anything my set up is easier.

And then it was the moment of truth; removing all the bolts holding the rocker cover in place, which I did in a cross-cross fashion, a la drum head tuning, to keep the release of tension/pressure even.

And so it was that, finally, I was able to get the cover off and see… And yea, verily, the cam belt was busted. The AA engineer spook sooth! I was able to gently work it out. And it’s lying there, rather tragically, in the above pic. But is the engine itself okay? I can’t tell, to be honest.

So, I managed to get the engine apart, and find the source of the problem. And the AA guy was right. Busted cam belt. Now what do I do? I guess I have a crack at replacing the timing belt? But that’s an even more complex and challenging job.