Another entry from the archives.

Within about six months, or perhaps less, of moving in, I got a load of floorboards off Freecycle, with a view to putting nice old wooden floors back into this property.

Downstairs the fooors are concrete slabs, with carpet overlaid. Upstairs it’s all chipboard.

In the end, however, the first room I did was the box-room. And I put in a parquet floor, bought for £60 off gumtree. It had come out of a beautiful old half-timbered cottage, somewhere in Herts, parts of which dated back the the 14/15th C.

I’m not sure what wood the parquet is. The seller said oak. It seems to be two types of wood, one a kind of mushroomy grey/beige, the other a more orange/yellow-ish colour. I reckon the former might be oak, whilst the latter is probably some form of pine.

After time-consuming and unsuccessful attempts at removing the bitumen type fixative from the underside of some parquet tiles, I knocked up a ‘quick’n’dirty’ table-saw, and proceeded to trim the wooden bricks. A lot of work. And a lot of – ‘cough’ – sawdust.

I went through two circular saw blades, losing teeth and dulling them pretty durn quickly under the heavy workload. Laying the floor wasn’t easy, and I haven’t fond that good a job. But I’m happy enough with the result. It’s sooo much nicer than the horrid worn carpet we inherited from the previous owner.

The next areas of floor to get a make-over were the stairs and upstairs hallway. Ripping out and disposing of the carpeting was a dirty unpleasant job. But I kind of enjoyed it, ’cause I hated the carpet.

The stairs steps, which are a decent enough wood, were sanded and varnished, with the front vertical faces – which appear to be a cheap plywood – painted in an off-white.

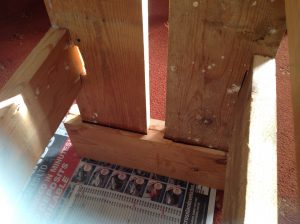

The upstairs hallway – is thus what’s sometimes called the ‘landing’? – was chipboard. I tore this up and kept it, for use as scrap wood. I recycled the floor itself from my Freecycle floorboard stash.

The tongue and groove profiles had been badly damaged when these old floors were torn out. It was quite a job finding segments that still had any profiling left. And in the end I gave up on trying. So some of this flooring interlocks, and some doesn’t.

One issue still unaddressed is the discrepancy of the skirting board height. They were fixed over the now missing carpet, and consequently there’s a gap ‘twixt them and my newly installed floorboards.

On one evening, the day, or rather the night I finished laying the floorboard, I made that classic mistake of working too long and too hard. It was approaching midnight, and I’d been hard at it (titter) all day. But, with the end in sight, rather than stop and continue the following day, I ploughed on.

And, with just one small area to put boards into, I lost my balance, and put my foot through the ceiling below, punching out a segment of plasterboard. Winded and wounded, I sat a while. But after a few minutes regaining my composure, I went back to work. And the flooring was complete.

The hole in the living-room ceiling stayed in a pretty sorry raggedly punctured state for over a year. It was only fairly recently I neatened the aperture into a small rectangle, and patched it with some plasterboard I had in the workshop.

With the hallway floor done, I then removed the appalling heavily textured Artex from the walks. Even using the massively expensive and reasonably effective Ex-Tex, this was a massive and horrible job. How I loathe Artex!

For colour, I wanted a bright, warm, vivid green. Something string, and full of character. None of your tepid Magnolia! An ornate gold-framed mirror at one end, over one of our several ‘nursing’ chairs, and a Freecycle sourced bookcase at the other, with a picture or two between, and this area is more or less done.

Some time later Teresa badgered me into putting up a curtain rail at the top of the stairs. I’m not sure what I make of this idea. It’s hardly practical. Indeed, it’s only really ornamental. The curtain pole and fittings we bought for a few quid from a local house-clearance bric-a-brac yard, whilst the green velvet is from the haberdashery section of Ely City Cycle Centre.

The original plan had been parquet for the box room, and then floorboards in the rest of the upstairs rooms. But, after the intensity of the work involved in doing the box room and hallway/stairs, when it came to the next room – our guest room – after removing more wallpaper and Artex (not sure which I hate most!?), I couldn’t face doing the floor as well.

So in the guest room I’ve currently simply ripped out the carpet, and then sanded and painted the chipboard flooring. This looks a bit rough. But, in that super-tough grey floor paint, it looks kind of cool as well.

This room also got a very vivid coloured paint job. The blue I was after should really be paler, and less intense than what we wound up with. And with a restored chest of drawers (Freecycle!), some bookshelves (ditto), and Hannah!’s nice old Victorian bed, all set off by a colourful Kilim from Alistair Hull, the room is both vibrant and full of character.

We considered letting this room to a full-time lodger. But as I really don’t want to share our home with other full time occupants, instead we’re letting it via Air&B. I was worried the strong blue might put people off. But it doesn’t appear to have.